Precision Sealing Solutions

Providing expert sealing gasket services designed to deliver reliable, durable, and high-performance sealing solutions for a wide range of industrial and commercial applications. Gaskets and sealing products offer a practical, supportive, and tailored approach to preventing leaks, reducing vibration, and improving operational efficiency, allowing you to maintain safe, reliable, and efficient systems with confidence.

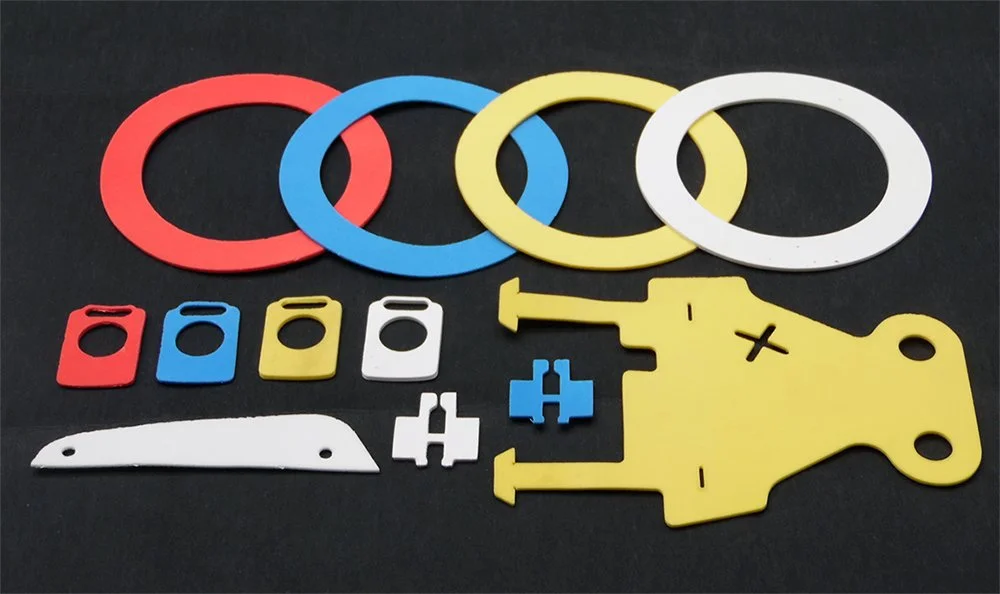

Sealing gaskets are critical components in many applications, forming a barrier between surfaces to prevent air, water, dust, gas, or fluid ingress. Manufacturing gaskets using high-quality materials such as EPDM, neoprene, nitrile, and silicone rubber ensures each product performs effectively under the demands of its operating environment. Whether you are looking to supply industrial machinery, protect building installations, or seal equipment in automotive, HVAC, or manufacturing sectors, sealing gasket solutions can help.

Sealing solutions are designed to balance protection, reliability, and long-term performance, giving you a clear, structured path to achieving leak-free and vibration-controlled systems. With professional guidance and technical expertise, you can be reassured that your sealing solutions are suitable for your circumstances and meet all operational and regulatory requirements.

Benefits of Sealing Gasket Solutions

There are numerous advantages to investing in high-quality, professionally fabricated gaskets. Correctly designed and manufactured sealing solutions help ensure that your systems remain leak-free, energy-efficient, and safe. By selecting the appropriate material and gasket type for your application, you can minimise wear and tear, reduce maintenance costs, and extend the service life of your equipment.

For applications with fluctuating pressures, high temperatures, or exposure to chemicals, gaskets can be customised to withstand these challenges while maintaining a tight seal. This ensures continuity of operations and reduces the risk of unplanned downtime.

Long-term planning is another key advantage. Many businesses need gaskets that can reliably perform over time under repeated stress or environmental exposure. By choosing precision-manufactured sealing solutions, you gain clarity, protection, and peace of mind, knowing that your systems are safeguarded by components designed to last.

Whether you require simple flat gaskets, complex multi-layer seals, or precision cut components, professionally fabricated gaskets support operational efficiency, regulatory compliance, and equipment protection.

Tailored Sealing Gasket Solutions

No two systems or applications are the same, which is why sealing gasket solutions are fully tailored to your specific requirements. Whether you are managing industrial machinery, HVAC systems, automotive assemblies, or manufacturing equipment, ensure that each gasket is designed and manufactured to meet your precise specifications.

The team works closely with you to select the most appropriate material, thickness, and design for your application, considering factors such as temperature, chemical exposure, pressure, and environmental conditions. Gaskets can be supplied in standard or bespoke dimensions, cut to exact measurements, or fabricated as part of multi-layer or bonded assemblies to suit complex applications.

With expert sealing gasket solutions, you’re not just purchasing a product, you’re gaining a partner in quality foam, sponge and rubber components, offering ongoing support, technical advice, and the assurance that your systems are protected by reliable, expertly fabricated gaskets.